ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project

39 Years. 110 Countries of Food Machine – ANKO

LP-3001 Food Machine for Making Chinese crepe, green scallion pie, pizza base, stuffed paratha, croissant donut

ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project

For the last 39 years, ANKO has been selling food machines worldwide by providing high-quality food processing machinery and excellent customer services. The skillful technology and flexible custom design have allowed ANKO to sell long-lasting and cost-effective food machines to over 110 countries.

Based on 39 years of food machine experience, the primarily collected recipe database has been a value-added deal for clients along with their machine purchasing. Later, ANKO started to sell production lines due to the market needs. One of the turnkey projects was a paratha production line for a large company in South Africa, which was a fun challenge for ANKO's engineers. Because of this order, ANKO has gained knowledge of turnkey project design, such as how a food machine can be modified to improve food quality by taking account of the weather temperature effect, design of flour sprinkle method and dough resting period, as well as the selection of flour.

The skillful technology and flexible custom design have allowed ANKO to sell long-lasting and cost-effective food machines to over 110 countries.

ANKO received an order for a paratha (also known as a rotli or chapati) production line from South Africa a few years ago. The client was one of the leading industrial Houses in Tanzania, and their large-scale business was just eye-opening. Ranging from production plant of sugar, flour, mineral water, ice cream, biscuits, fruit juice, and food additive to plastic packaging and transport services, you name it! After the order, everything went well. When the client had received the container; ANKO's engineers also flew over for installation after 23 hours' journey.

Paratha (also known as a rotli or chapati) is one of the most popular unleavened flatbreads in South Asia, and the ingredients are simple: flour, butter, salt, and water. It requires flour kneading, rolling, dough sheeting and resting as well as butter application. Using a food machine to simulate handmade process for making parathas 100% taste like homemade is ANKO's goal.

ANKO handled client's machine installation quickly and efficiently; electrical wiring, machine operation, and machine part check-up. ANKO's services didn't stop right after the inspection; food making was the next step. ANKO suggested wheat flour that contains 11% to 12% protein for getting the right texture of paratha. The client took them to one of the plants to pick the right flour. Without flour test equipment, ANKO's engineer just grabbed a handful of flour, kneading it in the palm to observe its stickiness. In the end, the right kind of flour was picked. "ANKO consistently invites food professors for staff training to enhance their food knowledge, which is very helpful for a situation like this." ANKO's engineer recalled. As a result, the right kind of flour was found for mass production.

Food Machine Customization of Outflow Section for Sheet Buttering

Supposedly, a thick block of butter would be wrapped up in a dough skin followed by kneading. However, the temperature was above 35 degrees in Tanzania, when the butter came out from butter mixer, it turned into liquid within half an hour. The butter was runny and came out fast, which increased the uncertainty of food quality. Because of that, ANKO modified butter mixer's outflow shape to slow down the flow. Also, a metal spatula was equipped to spread the butter evenly.

9 Step Food Processing Machine - Cold Air for the Dough Quality Consistency and How the Plant Design was Changed Due to the Dough Resting Process

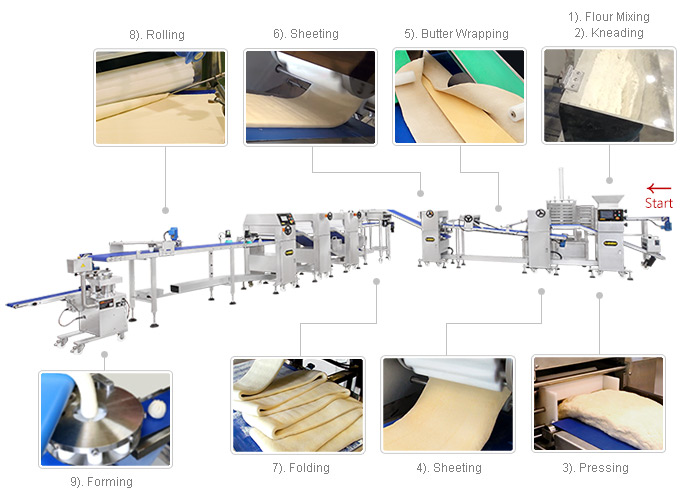

Paratha means layers of dough. When the flour powder is inserted in the food processing line, there are nine processing steps within fifteen minutes, including dough flour mixing, kneading, pressing, first-time dough sheeting, butter wrapping, second-time dough sheeting, folding, sheet rolling, forming and pressing. During the process, factors that would alter the characteristics of dough have to be removed, such as room temperature, fermenting period and flour type. So, the flour has been chosen. And as for the room temperature, it correlates to fermentation outcome. To loosen flour lattice, dough resting in the cold temperature helps. Thus, ANKO suggested an air-conditioned room. The next day, the client set up a 21 degree air-conditioned room, and the quality of food was enhanced.

For fermenting time, it was required to conduct thirty-five minutes dough resting in twelve minutes within 12 meters. In the end, ANKO decided to build a taller conveyor to save space.

So far, every aspect seemed to work correctly, from the beginning of flour sprinkler, the width of butter wrapping and flour dough folding to the dough ball forms.

| LP-3001 Automatic Layer & Stuffed Paratha Production Line | |

|---|---|

| Size | 10,350(L) * 7550(W) * 1800(H) mm ("L" arrangement) |

| Electricity | 220/380/415 V, 50/60 Hz, 3 Phase, 10 kw |

| Capacity (base on 130g/pc) | 3,000 pcs/hr |

| Capacity (base on 90g/pc) | 3,500 pcs/hr |

ANKO Food Machine Solutions for Dough Ball Pressing Issues to Make 19mm Pizza

Until now, an outflow mouth of butter mixer was customized, a buttered spatula was equipped, and an air conditioner was installed. Dough balls were formed and ready to be flattened into sheets. However, the dough ball stayed still after squashing. The stainless steel pressing machine, PP-2 (Automatic Filming and Pressing Machine), is a pressure press machine which is designed to make 80-gram dough balls into sheets.

As you can see, there are factors which influence the element of flour; where the wheat is from, the harvest season and the weather. Thus, modification of food machine is necessary to achieve food making goals. First, ANKO tried 30 minutes of dough resting but didn't work. Then moved the dough balls outside where the temperature was 32 degrees. It worked!

This same situation reminded ANKO whose client was a pizza supplier and requested a pizza machine that is capable of making 19 mm large size pizza. "No kidding, the metal plate bent trying to flatten dough balls." ANKO engineer recalled. Thus, ANKO increased conveyor's speed and lowered roller’s pace with a crosswise roller to obtain the desired thickness of dough sheet. A flour powder sprinkle, two dough resting conveyors (built tall to save space) plus rollers, 19mm flour dough skin was made, and the sheet skin stopped receding during processing.

On the fourth day of the trip, ANKO’s engineers met the boss, and he was thrilled with the food production line and its production capabilities. A year later, the client purchased another paratha production line to cope with the increasing sales.

| PP-2 | |

|---|---|

| Size | 2900(L) * 960(W) * 1470(H) mm |

| Stacking Conveyor | 1650(L) * 670(W) * 710(H) mm |

| Electricity | 220V, 50/60Hz, Single phase, 120W |

| Press Plate Size | 235mm |

| Product Diameter | Max. 200mm |

| Capacity | 1,500 pcs/hr |

| Air Consumption | 480L/min (@8kg/cm³) |

| Machine Weight | 700 kgs |

ARTICLE SECTIONS

- ANKO big investment move for high quality food machine supply

- ANKO's Food Processing Equipment Assists a Shoe Seller to Start a Food Business New

- 110 countries 39 Years - ANKO Food Machines Help You Reach Frozen Food Market New

- ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project New

- Pastry Sheet Processing Equipment - 5400 Pieces, 0.35mm - 0.4mm, Per Hour

- HLT-700 Dumpling Making Machine - ANKO

- ANKO Siomai Processing Equipment, As Good As Handmade

- ANKO Food Machine in Food Industry in Australia

- Filipino spring rolls special made from Jollibee

- ANKO sells spring roll machines to a world leading food company

- ABC Pastry buys dumpling food processing equipment from ANKO

- ANKO maamoul machine. kubba machine supply

- Paratha making machine with Heavy-Duty Durability

- Automatic fried rice machine

- Siomai making machine in France

- Siomai machine / Siomai making machine - innovative design for your food market

- Automatic encrusting and food forming machine for various types of wrappers

- 30 years turn-key project design

- Food making machine list

- Contact Anko, 30 years - food making machine expert

- ANKO FOOD MACHINE CO., LTD. Privacy Policy

PRODUCT CATEGORY

Search Related Products