ANKO Big Investment Move for High Quality Food Machine Supply

Better Food Making Equipment for Your Food Market

CNC 5 Axis Mill. Increased Design Team. High Production. Reasonable Cost

ANKO's 20 Million USD Food Making Machine Plant

If the objective of ANKO is to pursue world recognition of their food machines, then they are closer to achieving their goals. After over 30 years of food machine supply, ANKO decided to take a step further, a big step, to become one of the best in the food making machine industry. It took them 5 years and 20 million USD, but finally, ANKO’s new plant was built.

It was a big wow!

Why would a food machine company invest 20 million USD in their new plant? "To expand and improve our production and organization capability, we've decided to move. Once the decision was made, we started to look for land. It's a big change but we know it has to be done in order to grow." said Richard OuYang, general manager of ANKO.

Five years later, ANKO moved, from originally over 20,000 to 107,000 square feet. ANKO showed a complete new look and feel to their clients. As soon as the move was settled, ANKO started to recruit talent. New change, new goals, ANKO has lots of plans.

- ANKO's objective is to create food machines with innovative designs. That means finding engineers who can develop food machines with unique designs and in the end attract worldwide buyers. Within a year, ANKO would like to increase their production capability by:

- Tripling food machine production capability;

- Increasing total staff from 60 to 150 people;

- Raising RD team membership up to 35 people;

- Worldwide patent obtaining including Russia, Middle Eastern countries, U.S., Japan and more;

- Implementing Japanese 5S system (already starting);

- Purchasing a CNC 5 Axis Mill (arrived in Nov.);

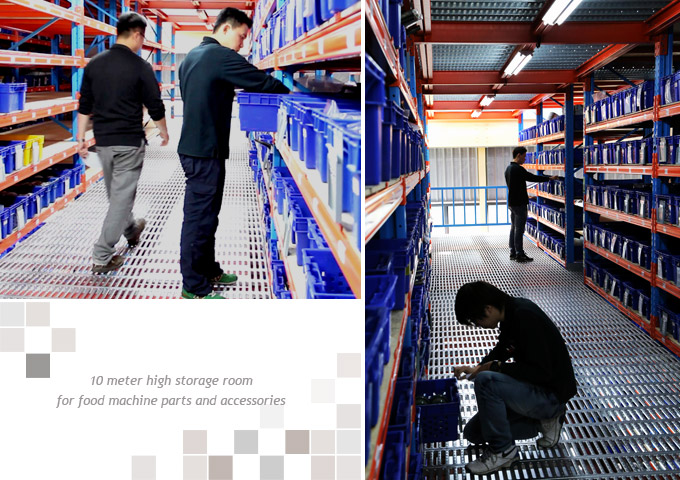

- Purchasing and inventory teams added.

Data Center and Server Room

ANKO is expanding and there is lots of info to secure, so the internet speed has to be stable. The fiber optic network design plays a crucial role in system reliability. At ANKO, the brand new up-to-date software, hardware and devises have been implemented to protect all the investment, it is just amazing.

Do you know you can start selling siomai in your country? Do you know there's a big potential for selling foods from other countries? ANKO has been selling food making machines for over 30 years in more than 106 countries. Their collected food knowledge and food machinery building/designing experience are all saved at the data center. The newly built large data center is created for anytime access. All of their clients’ information, food ingredients, and the designs, they are all stored in the data center.

One - stop production for your food making machine

In order to control the quality of every food making machine, ANKO is 100% involved in every part of design and manufacturing – from material purchasing, prototyping, manufacturing to shipping. With a 25% increase in the number of RD engineers, a mold developing room that makes 800 to 900 molds per year and a CNC 5 axis mill, ANKO is dedicated to providing one-stop production.

Two 40 footer container trucks

What's important for a buyer? No delaying! At ANKO, there’s a large shipping area that allows two 40-foot container trucks to load food processing equipment at the same time, which shows their high machine loading capacity. ANKO guarantees you a smooth working process to assure your machine is delivered on time.

EHEDG design for your food machine

1st Supplier in Asia, ANKO has become a member of EHEDG and started to design food machines based on EHEDG rules. It means that their machine is designed hygienically including food handling, preparation processing and the packaging of food.

No, no,

our food machine

WON'T become more expensive!

"Many people might have concerns about the price of our machines because of the big spending; actually, our new production and management system implementation has allowed us to use less time but to create more profit. It is a win-win for everyone." Says Richard.

Better food machine for you - ANKO

As soon as you walk in, the wide-open lobby and a digital signage with visitor's name and country's flag are shown to establish your warm welcome.

At the 1st floor, there are various meeting rooms, and each room is named after a flower and its painting is hung up on the wall. Again, client's name is displayed outside of the room. (ANKO even prepares a prayer room for religious visitors!) Inside the meeting room, the Chinese calligraphy on the wall is very artistic.

Food machine trials

Before customers arrive, communication is conducted through emails to have a basic understanding of the needs – the food that customers wish to make and the ingredients. Therefore, while meetings are being held on the 1st floor, meanwhile, , there is staff preparing ingredients and getting ready to demonstrate the food processing equipment on the 2nd Floor.

The 2nd floor is divided into two sections – small and medium sized food making machinery and large or production line food machinery. In the room, you can see dynamic molds (molds of numbers, animal shapes, sizes and resent trendy shapes) displayed next to the machine. "They are our valuable assets, which are designed by our engineering team.", said Richard OuYang.

In the demonstration room, there are many different types machines sitting there waiting for the trials. With no wires sitting on the floor, the high ceiling design leaves plenty of space for the people. Each food making machine has its own European standard power cord to meet multiple countries' power requirements. Its well-designed wire arrangement, cleanness and brightness of the place provide a totally comfortable experience for their visitors.

Automatic encrusting and forming machines, siomai machines and dumpling making machines, the demonstration room is equipped with all kinds of machines with ready-to-made ingredients as soon as you enter.

In the hallway, there are digital signages with dynamic foods from different regions for visitor's references. "There are so many foods from different countries, we hope this information can help our clients to create different markets with new ideas.", says Richard.

The ingredients for your food machine

There's a food storage room, there are ingredients, both local or from abroad, for clients to make food. "Flours can be varied based on the regions, at ANKO, we would cook with both flours, ours and clients', to show the differences," says Richard. "In addition, food making and preparation room is designed meeting food hygiene qualifications; and you can steam, cook, boil and deep fry food after it is made by food making machines.".

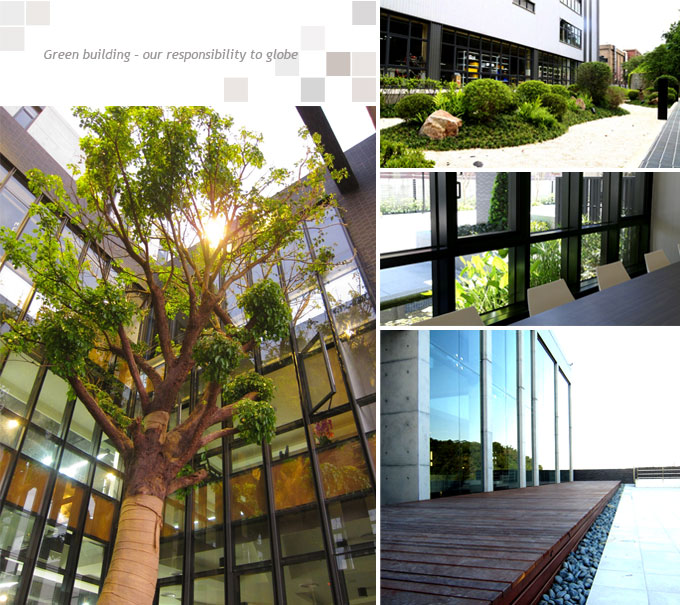

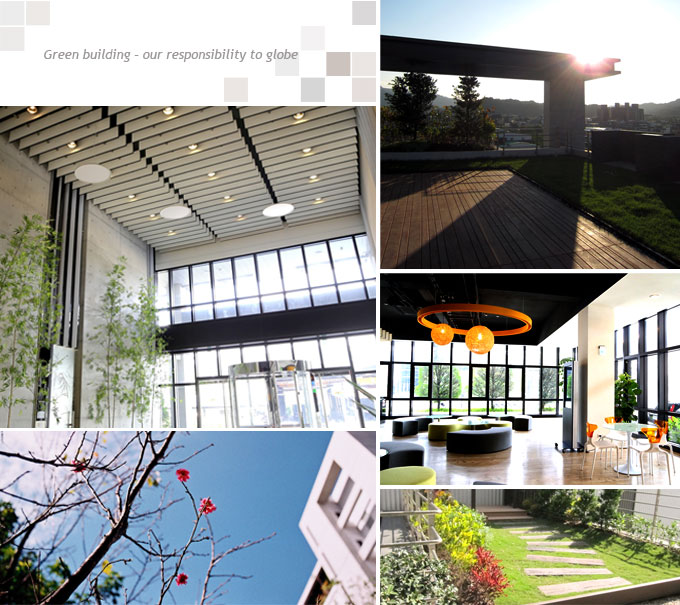

Green building – our responsibility to globe

Water collecting system, energy saving building material and the easy and simple cement design, they are all designed to be cost effective and at the same time to be environmentally friendly.

ANKO's Work Environment

It's a peaceful and green working environment. If you look outside from the glass wall, you'll see an 80 years old tree growing with prosperity. Antiques, calligraphy and Chinese poems are located in dynamic places with elegance, and at the same time, colorful office furniture delivers some excitement to mix with it.

To work with others, ANKO has an audio-visual center that can accommodate more than 50 people, where they communicate, negotiate, learn and teach with people from different countries, but all have the same interests – food machine.

ANKO's work philosophy

ANKO cherishes their employees, for each department, there’s a color to represent the team. And the color is used to apply on furniture as well. The large space for working area, Eco friendly lighting design, custom made office chairs, anytime meeting arrangements, food courts, bars and rooms for resting, all the set up is cozy and relaxing.

"It is important to define the core values from which we create our culture, our brand, and our work. Overall, we hope our environment can create a fun and relaxing working environment in order to generate more ideas and achieving mutual goals.", said Robert OuYang, president of ANKO.

Work hard,

play hard!

Halloween parties, birthday parties and activities are regularly held at ANKO. To celebrate Halloween in the new location, everyone was wearing a halloween costume and putting on creepy halloween makeup just for fun!

ARTICLE SECTIONS

- ANKO big investment move for high quality food machine supply

- ANKO's Food Processing Equipment Assists a Shoe Seller to Start a Food Business New

- 110 countries 39 Years - ANKO Food Machines Help You Reach Frozen Food Market New

- How ANKO Provides Food Machine And Delivers Professional Solutions To Win Client's Heart New

- ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project New

- Pastry Sheet Processing Equipment - 5400 Pieces, 0.35mm - 0.4mm, Per Hour

- HLT-700 Dumpling Making Machine - ANKO

- ANKO Siomai Processing Equipment, As Good As Handmade

- ANKO Food Machine in Food Industry in Australia

- Filipino spring rolls special made from Jollibee

- ANKO sells spring roll machines to a world leading food company

- ABC Pastry buys dumpling food processing equipment from ANKO

- ANKO maamoul machine. kubba machine supply

- Paratha making machine with Heavy-Duty Durability

- Automatic fried rice machine

- Siomai making machine in France

- Siomai machine / Siomai making machine - innovative design for your food market

- Automatic encrusting and food forming machine for various types of wrappers

- 30 years turn-key project design

- Food making machine list

- Contact Anko, 30 years - food making machine expert

- ANKO FOOD MACHINE CO., LTD. Privacy Policy

PRODUCT CATEGORY

Search Related Products