ANKO food machine in food industry in Australia

Great forming and wrapping technology for your food machine

Australian's only choice – ANKO food machine

ANKO Food Machine in food industry in Australia

Sanxia, Taiwan -- Over the decades since immigration movement, increased Asian communities have enabled ANKO to introduce their food machine to support the large consumers. Now, Asian cuisine not just purchased by certain people, it is a trend and a food selection. You can easily find frozen food such as steam buns, siomai, dumplings, Chinese hamburgers, fried rice, spring rolls and dim sum at any supermarket. Furthermore, they can be accessed at a food court in the mall. For years, ANKO's food machines have provided immigrants chances to pursue better lives in Australia, which is why they leave their hometown in the first place.

ANKO Food Machine for Sydney Best Dim Sim and Sun Circle Food Manufacturer in Australia

Estimated over 24 million population and 2.4 million Asians with Asian ancestral background, the market of food industry is big. Sydney Best Dim Sim and Sun Circle both started with one food machine and slowly expanded into food processing plants.

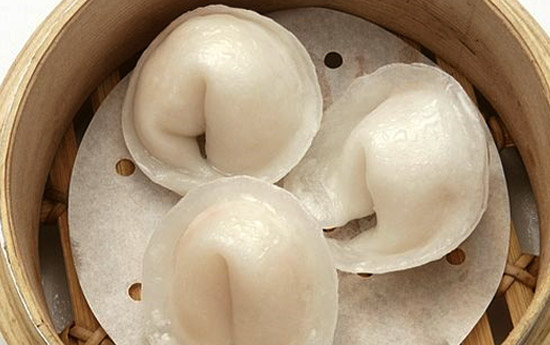

Sydney Best Dim Sim sells a full range of authentic traditional Cantonese style dim sim, hot and frozen, which can be accessed at restaurants located in Cabramatta, Eastwood, Campsie and Chinatown in Australia. Backed by a certified central kitchen which excesses of 500m² and ANKO's food processing equipment, Sydney Best Dim Sim provides food with consistent quality.

In 2012, besides shrimp dumpling processing equipment, which has 4,000 per hour production capability and changeable mold selection, siomai processing equipment (5,000/hour) were ordered for the 1st time. The next year, a food machine with higher production capacity was requested. In 2015, newly designed big size B.B.Q bun and egg custard bun processing equipment (SD-97L) was introduced. Sydney Best Dim Sim's food business was profitable. Regardless of providing food machine issue resolution, communication, overall customer satisfaction, ANKO's competent after sales service is acknowledged. Currently, there are dumpling making machine (HLT-700XL), siomai making machine (HSM-600J), automatic encrusting and forming machine (SD-97L) at the food processing plant.

ANKO's Food Machine for Sun Circle Food in Australia

Sun Circle Food's logo can be found everywhere at the supermarket in Australia. For the last 13 years, Sun Circle Food has purchased food processing lines from ANKO for making Chinese and Japanese dumplings, pork steam juicy buns, siomai and wontons.

As soon as you walk into Sun Circle's food processing plant, you can see many automatic food making lines operating non-stop making dumplings, gyoza, siomai, etc. Food machines such as dumpling processing equipment (HLT-700 and HLT-700XL), siomai processing equipment (HSM-600), automatic double-line wonton machine (HWT-400), gyoza making machine (AFD-888), automatic dough sheet making machine (ABS-220) to fulfill each client's stomach.

Sun Circle Food's plant is HACCP certified, an industrial heavy duty freezer is equipped, and seven food processing lines are constantly operating to meet the market demands. ANKO has been working in close collaboration with Sun Circle Food to explore the food market in Australia, and now they are again ready for the next goals - Russia and China.

- Features of AFD-888 gyoza making machine

- Dough is sheeted through continuous pressing rollers. After boiling, the dumpling wrapper is tasty lilke handmade.

- With automatic dough wrapper residue recycle device.

- Filling is kept in good texture.

- A special piston filling device keeps all the ingredient in good condition and taste.

- High capacity and various handmade-like patterns for choice.

| Dimension | (L)2000mm * (W)2450mm * (H)250mm |

|---|---|

| Electricity | 220/380V, 50/60hz, 3phase, 3.5kw, Air supply |

| Capacity of hopper | 46L |

| width of Sheet Roller | 230mm |

| Weight of Product | 18~20g, 24~26g, 28~30g (*Custom made is available) |

| Machine weight | 1,400kgs |

About ANKO's Food Machine - your life long business partner

HLT-700 was the 1st dumpling making machine developed to make Chinese dumplings. By using the forming and wrapping technology, ANKO also developed changeable mold to enforce its multiple performances. The machine makes over 3,000 to 10,000 pieces of dumplings per hour with PLC control system. Along with dumpling processing equipment, siomai making machine (HSM-600) is one of the best-sold food machines. The pastry sheet's thickness is designed to achieve perfect wrapping processing. Siomai making machine produces 6,000 siomais every hour.

ANKO's food machine is customized to meet various purposes; providing longer dough rest time, increasing substantial production capability, cooking temperature control, designing of specific wrapping method and mold design, particular pastry sheet thickness, conveyor belt with cooling system, single or double pastry sheet baking barrel, recipe adjustment, food processing equipment arrangement for processing plant, food machine troubleshooting, 24 hour after service and more. ANKO's comprehensive food machine service is the reason why they are capable of selling to over 110 countries.

Middle Eastern and Indian Food Machine from ANKO

Australia's food industry has a great potential based on the immigrants from all over the places. Thus, Middle Eastern and Indian food have been targeted in the food industry as well. Ranging from Middle Eastern cuisine such as sababa (HLT-660B), kubba (SD96L), mammoul (AL-240) to Indian cuisine including chapatti (APB), (Lacha Paratha LAP-2200) and samosa (DS650) (PMM500) food processing line, ANKO's food machine technology is always one step ahead.

Work flow of dough sheeter DS-650

Dough kneading

Dough ball flattening

Dough ball flattening

Butter adding

Dough kneading contained with butter

Dough sheet flattening

Dough sheet pressing

Dough sheet rolling

ARTICLE SECTIONS

- ANKO big investment move for high quality food machine supply

- ANKO's Food Processing Equipment Assists a Shoe Seller to Start a Food Business New

- 110 countries 39 Years - ANKO Food Machines Help You Reach Frozen Food Market New

- ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project New

- Pastry Sheet Processing Equipment - 5400 Pieces, 0.35mm - 0.4mm, Per Hour

- HLT-700 Dumpling Making Machine - ANKO

- ANKO Siomai Processing Equipment, As Good As Handmade

- ANKO Food Machine in Food Industry in Australia

- Filipino spring rolls special made from Jollibee

- ANKO sells spring roll machines to a world leading food company

- ABC Pastry buys dumpling food processing equipment from ANKO

- ANKO maamoul machine. kubba machine supply

- Paratha making machine with Heavy-Duty Durability

- Automatic fried rice machine

- Siomai making machine in France

- Siomai machine / Siomai making machine - innovative design for your food market

- Automatic encrusting and food forming machine for various types of wrappers

- 30 years turn-key project design

- Food making machine list

- Contact Anko, 30 years - food making machine expert

- ANKO FOOD MACHINE CO., LTD. Privacy Policy

PRODUCT CATEGORY

Search Related Products