Pastry Sheet Processing Equipment - 5400 Pieces, 0.35mm - 0.4mm, Per Hour

Batter Mixing Machine – 10 Minutes Processing Time

Pastry Sheet Food Machine – U.S. Made Conveyor Belt

ANKO food machine prevails over handmade pastry sheet

BM-150

BM-150

Batter mixer BW-400

BW-400

Batter storing cooling & resting tank HLT-700

HLT-700

Multipurpose filling & forming machine

Sanxia, Taiwan -- ANKO FOOD MACHINE CO., LTD. (ANKO)'s engineering team succeeds in achieving goals to design a pastry sheet and crepe food machine that allows production of pastry sheet-related foods, such as samosa, blini, egg roll and spring roll with maximum 5400 pieces, 0.35mm - 0.4mm, per hour.

Combine other food processing equipment, including mixer (BM-150), batter storing cooling compressor (BW-400), and a completed production line is ready. Plus, frying and packaging machines can be purchased if needed.

Remarkably baked and high quality production of pastry sheets thus resulted in great recognition and sold thousands worldwide in 110 countries, including to Global Gourmet Pvt. Ltd., an Indian food manufacturer with increasing orders. They decided not to import pastry sheet, from Malaysia, and instead started by buying one pastry making machine. And now they already have five food processing lines with single and double baking barrels constantly making authentic Indian cuisine for day-to-day demands.

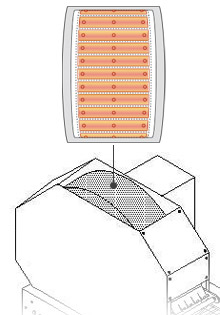

Pastry sheet baking barrel, 48 - heating plate to bake perfect

ANKO's pastry sheet making equipment is designed using electricity heating system, rather than gas heating system. The outcome of wrapping will depend on the firmness of the sheet. The hardness of pastry sheets baked between 1 to 3 degrees can make the wrapping process turn out quite differently. Too hard, pastry sheet shifts on the conveyor belt due to the momentum; too soft, it slides away. Therefore, baking temperature has to be accurate. ANKO's electricity heating system is designed to travel nine meters per minute and constantly monitored by temperature controller automatically to maintain temp in ideal range. For that reason, each pastry sheet is baked evenly.

There are 20, 45 and 90 SRP series pastry sheet making machines are categorized based on capacity – single and double barrel.

Batter mixing food machine – empowered shear force with time efficiency

Batter mixer

Batter mixer Batter storing cooling and resting tank

Batter storing cooling and resting tank

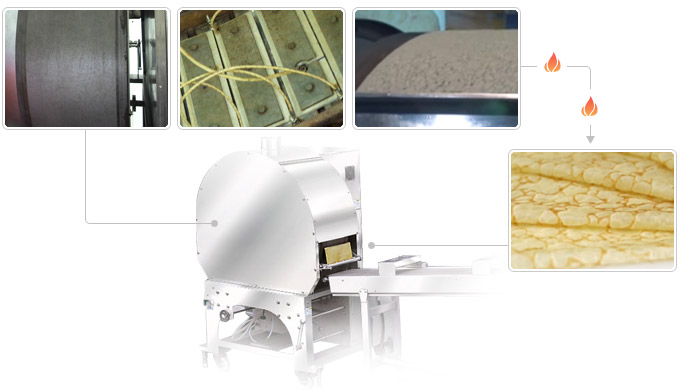

Before baking, there are a few food machines that are involved in the process; batter mixing machine, cooling compressor and food depositor machine. ANKO's newly designed batter mixing equipment is designed with high shear, high energy, and is extremely efficient, which has shortened the processing time from 40 to 10 minutes. It reduces the cooling period for great mixing performance.

The batter storing and cooling and resting tank, BW-400, is equipped with a cooling compressor to lower the risk of contamination. It also allows you to continue mixing to enhance the quality of batter.

Pastry sheet food machine – U.S. made conveyor belt

ANKO uses U.S. JBT Corporation's conveyor belt to enhance the quality of delivery. Conveyor cooling belt's length varies depending on the following steps - wrapping or stacking. If you are making pastry, stacking is necessary, if food depositing, wrapping occurs. That said, if you wish to make spring rolls, samosa, blini or egg rolls, extra equipment is needed.

ANKO custom made wrapping and forming machine

In the U.S., Europe and Asia, food depositing and forming is done varyingly. In the U.S., cup shaped carrier would include mold making, which is costly; in Europe, conveyor belt along with air blow to flip pastry sheet, suitable for heavier food and thick pastry sheet, is used. But these are not favored in Asia. ANKO's 38 years of outstanding wrapping and forming technology has turned frozen food into daily comfort food.

ANKO – food machine manufacturer for 38 years

With all the selections of food machines, how do you find one that can capture consumers' hearts and also make it a profitable business in the fast-growing food industry? What matters in food processing equipment is technology. After three generations of modifications, ANKO's food machine solutions are innovative, and they are looking forward to designing better food machines to generate better food in the lucrative food industry. ANKO, a comprehensive food machine manufacturer from Taiwan with collected technology based on 38 years of experience.

Automatic spring roll and samosa pastry sheet machine - SRP series

Pastry sheet production

Feeding

Spraying & baking

Cooling

Cutting, counting & Stacking

| ITEM | SRP-20A | SRP-45A |

|---|---|---|

| SRP Series |  |

|

| Unique and Reliable Design |

|

|

| Dimension (mm) | 3500 (L) * 930 (W) * 1570(H) | 5800 (L) * 1200(W) * 1800(H) |

| Power | 19Kw | 35Kw |

| Pastry Thickness | 0.4~0.8mm | |

| Pastry Maximum Width | 220mm (special size) | |

| Production Capacity (Pastry Sheets Per Hour) | ||

| Spring Roll | 900~1200 | 2400~2700 |

| Samosa | 2700~3600 | 7200~8100 |

ARTICLE SECTIONS

- ANKO big investment move for high quality food machine supply

- ANKO's Food Processing Equipment Assists a Shoe Seller to Start a Food Business New

- 110 countries 39 Years - ANKO Food Machines Help You Reach Frozen Food Market New

- ANKO's Paratha Production Line - From Individual Food Machine to Turnkey Project New

- Pastry Sheet Processing Equipment - 5400 Pieces, 0.35mm - 0.4mm, Per Hour

- HLT-700 Dumpling Making Machine - ANKO

- ANKO Siomai Processing Equipment, As Good As Handmade

- ANKO Food Machine in Food Industry in Australia

- Filipino spring rolls special made from Jollibee

- ANKO sells spring roll machines to a world leading food company

- ABC Pastry buys dumpling food processing equipment from ANKO

- ANKO maamoul machine. kubba machine supply

- Paratha making machine with Heavy-Duty Durability

- Automatic fried rice machine

- Siomai making machine in France

- Siomai machine / Siomai making machine - innovative design for your food market

- Automatic encrusting and food forming machine for various types of wrappers

- 30 years turn-key project design

- Food making machine list

- Contact Anko, 30 years - food making machine expert

- ANKO FOOD MACHINE CO., LTD. Privacy Policy

PRODUCT CATEGORY

Search Related Products